A new process patented by the Oak Ridge National Laboratory (ORNL) allows the recovery of rare elements from permanent magnets of electronic devices and reuse them to produce new magnets for electric motors equivalent to those made with new materials.

A team of researchers at the Oak Ridge National Laboratory (ORNL) has developed a process to extract rare elements from permanent discarded magnets from used hard drives and other electronic sources that use them in their composition. The patented process is capable of recovering 97% of the rare elements in the form of oxide, with a purity of 99.5%.

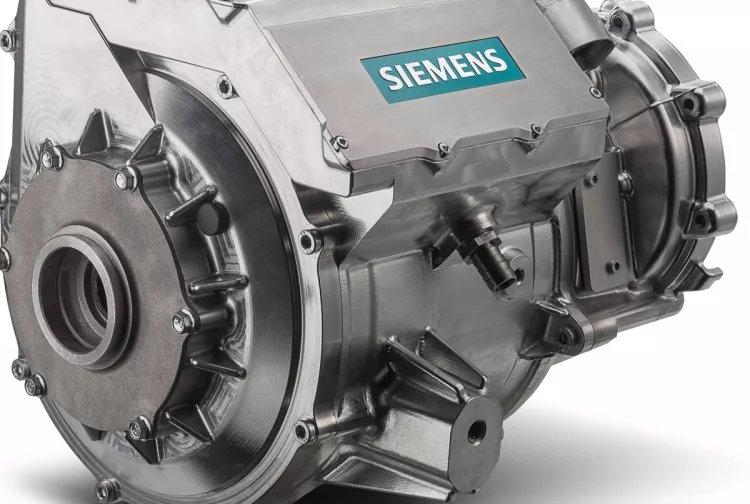

Rare earth elements are currently essential for synchronous electric motors of electric vehicles. Embedded in its rotor are permanent magnets formed by these elements that provide a magnetic flux when they are magnetized with another magnetic field, not losing their properties once the cause that causes the magnetism ceases. Thanks to them, no external excitation or brushes are needed to generate the magnetic field in the rotor and spin it when exposed to the externally generated field in the stator, which makes them more compact and simple.

After their industrial generalization in the 1990s, they increased their demand in the automotive industry until, in 2018, manufacturers opted, in 93% of cases, to provide their electric cars with permanent magnet motors. They are scarce, expensive, and difficult to recycle.

The new patent extends the laboratory demonstration process announced in October last year. ORNL is working with Momentum Technologies to expand production volume to offer a commercial lot that includes rare earth oxides. In 2017, the company already developed the technology to print three-dimensional magnets, and with this new development, it plans to produce the first 3D-printed magnet made from recycled materials.

The objective of the project is to recover hundreds of kilograms of rare earth oxides every month and validate, verify and certify that they can be used by manufacturers to make magnets equivalent to those made with virgin materials. Until now, no commercial process was able to recycle pure rare earth elements from electronic equipment magnets. According to the studies, 2,200 million personal computers, tablets and mobile phones worldwide are expected to be replaced in 2019.

BMW plans to develop next-generation electric drives together with British carmaker Jaguar Land Rover. Companies are hoping to bring new electric vehicles to market faster. Both top-of-the-line manufacturers have recently posted losses in the car business and… Continue reading

The EQC will be the first electric car of the EQ family. It is already available for order and from July you will start with the deliveries. We tell you what you need to know about the first electric SUV from Mercedes. The Mercedes EQC is… Continue reading

The competition to develop more competitive batteries is fierce. The latest research from Stanford University and the National Accelerator Laboratory (SLAC) has presented a major discovery that will allow increased energy density and lithium… Continue reading

In order to be able to sell the production version of the all-electric Renault 5 Prototype planned for 2023 at a profit, Renault is analyzing the LFP batteries. The price range of the Renault 5 should be between 20,000 and 30… Continue reading