The competition to develop more competitive batteries is fierce. The latest research from Stanford University and the National Accelerator Laboratory (SLAC) has presented a major discovery that will allow increased energy density and lithium battery safety.

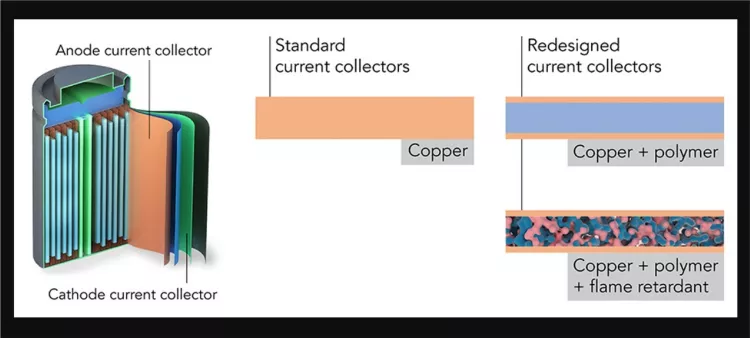

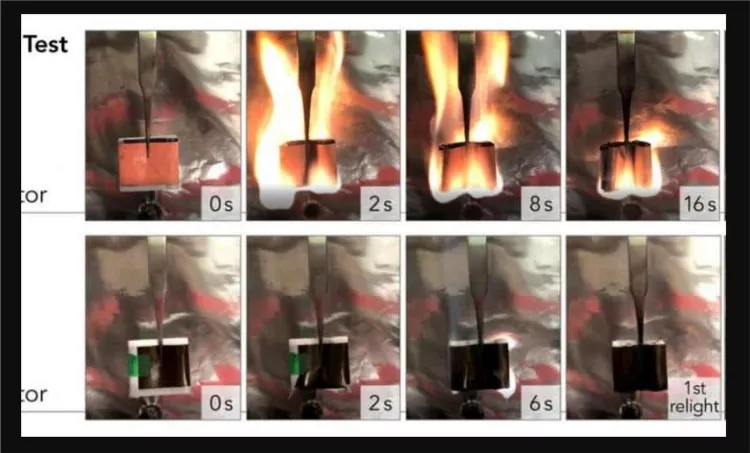

The works have focused their efforts on the redesign of the current collector. A component that currently has been tried to solve with a thinner or porous design, something that means reducing weight but at the cost of increasing the risk of fire, which has led many manufacturers to add more electrolytic material.

Lithium batteries have a pair of current collectors, one at the anode and one at the cathode, which works with the device's two electrodes to distribute current flow in either direction. Today's current collectors are typically made of copper foil or aluminium foil, making them one of the heaviest components in the battery, sometimes accounting for up to 50% of the total weight of the device.

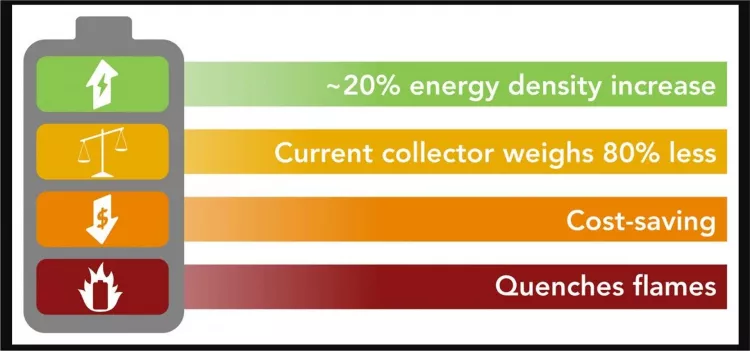

According to Yi Cui, a professor at SLAC and Stanford, "The current collector has always been considered dead weight, and until now it hasn’t been successfully exploited to increase battery performance. But in our study, making the collector 80% lighter increased the energy density of lithium-ion batteries—how much energy they can store in a given weight—by 16-26%. That’s a big jump compared to the average 3% increase achieved in recent years.".

The Stanford University team have been experimenting with a lightweight polymer called polyimide. This was integrated with a fire retardant called triphenyl phosphate. One of the great advantages of this approach according to its developers is that the new collector should be easy to manufacture and also cheaper, by replacing some of the copper with an inexpensive polymer.

Some achievements have already been patented, and they have even been sent to different battery manufacturers to begin exploring the possibilities of this exciting advance that will help increase the energy densities of batteries, improve safety, and even reduce their costs. via nature.com.

A new process patented by the Oak Ridge National Laboratory (ORNL) allows the recovery of rare elements from permanent magnets of electronic devices and reuse them to produce new magnets for electric motors equivalent to those made with new… Continue reading

Opel wants to build the largest German electric car battery factory in the town of Kaiserslautern, as announced by Michael Lohscheller. The "one billion euro" plant will be built in partnership with the French company Saft, a… Continue reading

Samsung researchers have presented the prototype of a solid-state battery cell, which should help electric cars reach a range of 800 kilometres and withstand over 1,000 charging cycles. There is also a solution to the problem of dendrite… Continue reading

The battery life of an electric car depends a lot on how to use the car, on the lifestyle of the driver, whether he is a CEO or a taxi driver. Fast charging takes the life of the electric car battery. Why did I refer to these two jobs?… Continue reading